铸造碳化钨产品的牌号及规格 Grades and specifications of cast tungsten carbide products铸造碳化钨粉末的牌号按筛分时粉末通过筛网的网目数来确定。

产品牌号表示方法为:

Cast tungsten carbide products are supplied in two forms as powder (f) and tubes(g)

The grades of cast tungsten carbide powder are determined by the no, of meshes of the sieve it passes through.

1. 粉状铸造碳化钨合金粉的外观呈银灰色,外形为多棱状。使用方法主要为喷焊、浸渍、喷涂。牌号及规格如下表:

- Cast tungsten carbide powder is silver grey in outward appearance and multi-prism in shape. The applications and mainly spray welding, immersion and spray coating. The grades and specifications are shown in the table below.

| 粉状铸造碳化钨牌号及规格 |

GRADES AND SPECIFICATIONS OF CAST TUNGSTEN CARBIDE |

牌号 |

粒度范围(网.目) |

相应颗粒尺寸(MM) |

GRADE |

RANGE OFGRAIN SIZE(MESH) |

SIZE CORRESPONDING TO MM |

YZ20-30f |

-20- +30 |

0.85∽0.60 |

YZ30-40f |

-30- +40 |

0.60∽0.425 |

YZ40-60f |

-40- +60 |

0.425∽0.25 |

YZ60-80f |

-60- +80 |

0.25∽0.18 |

YZ65-100f |

-65- +100 |

0.21∽0.15 |

YZ100-140f |

-100- +140 |

0.15∽0.106 |

YZ150-200f |

-150- +200 |

0.106∽0.075 |

YZ80-200f |

-80 - +200 |

0.18∽0.075 |

YZ100-200f |

-100- +200 |

0.15∽0.075 |

YZ200-400f |

-200- +400 |

0.075∽0.038 |

YZ270-600f |

-270- +400 |

0.53∽0.020 |

2.

管装铸造碳化钨焊条是以铸造碳化钨为硬质相,以优质低碳钢为粘结金属而制作的耐磨焊条,使用方法主要采用氧一乙炔焰堆

焊、电弧堆焊。其牌号及规格好下表:

Tubular cast tungsten carbide welding rods are wear resistant welding rods manufactured with cast tungsten carbide as the hard phase and super quality low carbon steel as the binding metal .The way of applications is mainly build-up welding via oxygen-acetylene flames, and electric and .The grades and specifications are showed in the table below:

| 管装铸造碳化钨焊条牌号及规格 |

GRADES AND SPECIFICATIONS OF TUBULAR CAST TUNGSTEN CARBIDE WELDING RODS |

牌号 |

粒度(网目) |

钢管尺寸(毫米) |

|

比例(%) |

GRADE |

SIZE (MESH) |

DIMENSION OF STEEL TUBE(MM) |

|

RATIO(%) |

|

|

直径 |

长度 LENGTH |

铸造碳化钨 CAST WC |

钢管 STEEL TUBE |

|

|

DIAMETER |

YZ20-30G |

-20∽+30 |

|

390+-5 |

60~65 |

35~40 |

YZ30-40G |

-30∽+40 |

|

390+-5 |

60~65 |

35~40 |

YZ40-60G |

-40∽+60 |

|

390+-5 |

60~65 |

35~40 |

YZ60-80G |

-60∽+80 |

|

390+-5 |

60~65 |

35~40 |

应用范围

3.铸造碳化钨的应用范围

Range of applications of cast tungsten carbide

铸造碳化钨作为一种耐磨补强材料使用范围是很广的,主要有:

- 矿业方面:岩石破碎机配件、截煤机齿、麻花钻头、刮土机零件、钻孔器齿冠、鱼尾钻头、牙轮钻头齿部堆焊、球齿牙轮钻头的爪背的堆焊等。

- 土建方面:铲斗刃、推土机零件、刮板、挖掘机零件、拌土机零件、拖拉机履带面等。

- 农业方面:脱谷机柱齿、钻头刃口、犁刀、铲齿、饲料粉碎机锤片等。

- 建筑方面:水泥螺旋粉碎机、水泥装载机、制砖业的成型抹子、切割刀、和土机零件、挖窑沟铲等。

其他方面:钢铁、机械、制糖、木材、造纸、发电厂的粉煤锤头等均可使用

- 铸造碳化钨进行堆焊,使零部件的使用寿命大大提高。

Cast tungsten carbide as a wear resistant strengthening material has a wide range of applications and these mainly are:

- Mining industry :Build-up welding of fitting parts of rock crushers, auger tips, twist drills, scraping plates of scrapers, teeth’s coronas of drilling tools, fishtail drills, teeth of tricone bits and support claws of tricone bits, etc.

- Civil construction: The edges of shoveling buckets, parts of bulldozers, scraping plates, parts of earth agitators, clawer belts of tractors, etc.

- Agriculture :For columnar teeth of threshers, edges of drills, ploughs, teeth of shovels, etc.

- Architecture: For spiral crushers for cement, cement loaders, brick scrapers, cutters, earth mixing machines, kiln digging shovels, etc.

- Miscellaneous: Build-up welding can be used in industries of steel, machinery, sugar, wood, papermaking and on hammers for crushing coal in power plants, etc. substantially increasing the lifetime of parts and components.

(一)铸造碳化钨产品的选用

Selection of cast tungsten carbide products

铸造碳化钨粉是一种高熔点合金,使用时需与铁基合金(或镍基、钴基、铜焊料)配合使用,铸造碳化钨粉粒度的选择,应根据零件的受力情况、工作状况等而定。通常粗颗料用于焊层较厚,工件要求耐磨损。细颗粒用于冲击负荷较大、磨粒磨损现象严惩的工件部位,使用方法主要为喷焊、浸渍、喷涂。从目前使用情况来看,40—60目产品被广泛应用于耐磨电焊条的制作,65—100目、100—140目、140—200目、200—400目及80—200目广泛用于制作金钢石钻头骨架。

Cast tungsten carbide is a high melting point alloy and it should be used together with iron-based alloys(or Ni-based, copper solders),The selection of the grain size of cast tungsten carbide should be based on the force to bear by the parts and working conditions, etc. Generally cast tungsten carbide of coarse grain size is suitable for thick welded layers of parts that require wear resistance. Cast tungsten carbide of fine grain size is used for portions workpieces with great impact loads and with serious wear by abrasive particles. The main applications are spray welding, immersion and spray coating. As noted from the present applications, cast tungsten carbide of 40-60mesh is widely used for making wear resistant welding electrodes and what is widely used in making skeletons of diamond drills is cast tungsten carbide of 65-100mesh,100-140mesh,140-200mesh,200-400mesh and 80-200mesh.

同样管状铸造碳化钨焊条的选用也应根据工件的工作条件而确定,通常焊条直径较大、铸造碳化钨颗粒较粗的用于焊层较厚,防滑防割性能好的工件,如YZ20-30g焊条应用于制砖及水泥行业。焊层要求薄而平整的,应选择直径小的细颗粒铸造碳化钨焊条。如YZ40-60g、YZ60-80g焊条应用于制糖及饲料粉碎行业。

As is the case, the selection of tubular cast tungsten carbide depends on the working conditions of the workpieces. Generally cast tungsten carbide of bigger tube diameters and of coarser grain size is used for welding workpieces with thick welded layers and with good skid and cut resistance performances, for example,YZ20-30g welding rods are used in brick and cement industry. Welding rods of small tube diameters fine grain size should be chosen if thin and even welded layers are required, for cxample,YZ40-60g and YZ60-80g is used in suger making and fodder crushing industries.

使用实例

1. 牙轮钻头牙爪罩板堆焊;牙轮钻头的牙爪罩板,在使用过程中磨损很快,又因较薄,磨损后轴承就外露,岩粉碎屑进入牙轮的转动部位,造成钻头的过早报废。如对罩板堆焊一层铸造碳化钨,可提高其耐磨性,从而延长钻头的使用寿命。

The build-up welding of support claws of tricone bits: The support claws of triconbe bits wear very quickly during operations. if a layer of cast tungsten carbide is build-up welded on the support claws, if will improve their wear resistance and prolong the lifetime of rticone bits.

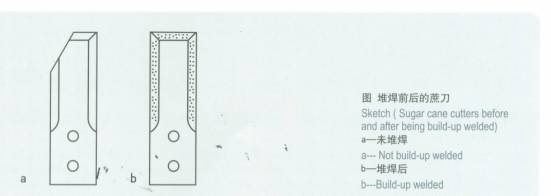

2. 切蔗刀堆焊:切蔗刀是糖工业中用以破碎甘蔗的一种重要工具。由于蔗刀易磨损变坏,影响出糖率。停要换刀时间长,劳动强度大。经堆焊铸造碳化钨后,蔗刀的使用寿命显著提高,较原来蔗刀提高十多倍。且可反复堆焊、反复使用,大大地降低钢材消耗。以外,在制糖工业中,用于堆焊高效破碎机磨泵中的齿板和齿条,也取得了良好的效果。

The build-up welding of cane cutters: Sugar cane cutters are an important tool in cane sugar industry in crushing sugar canes. As the cutters wear considerably, if takes a long gime in changing the cutters, increasing the intensity of labor. The efficiency in crushing sugar canes deteriorates with the wear of the cutters, affecting the yield of cane sugar. The lifetime of sugar cane cutters increases substantially after they are build-up welded with cast tungsten carbide powder achieving an increase of more than 10 times. And the cutters can be build-up welded again after they are worn out, so the cutters can be used repeatedly, greatly reducing the consumption of steel.

3. 收尘风机叶片堆焊:收尘风机是使用较广的设备。其叶片是用3号钢制作的,厚度为6mm,在使用中叶片磨损很快,经堆焊铸造

碳化钨合金后,叶片的寿命可提高十倍以上。

The build-up welding of the air vanes of dust collecting blower: Dust collecting blowers are a widely used equipment. The vanes wear quickly in operations and the lifetime of air vanes can be increased by more than 10 time if they are build-up welded with cast tungsten carbide.

4. 大齿轮咬合面堆焊:大型轧机和压榨机的传动大齿轮在工作过程中,齿的咬合面产生大的挤压力和磨擦力易磨损和形成凹坑,齿厚减薄,因而报废。采用铸造碳化钨修补后,可以延长使用寿命。堆焊采用的铸造碳化钨颗粒,以细的为佳。

The build-up welding of the meshing surfaces of big gear wheels :During operations of the big driving gears of big rolling mills and squeezers, the meshing surfaces wear easily and form cavities due to the squeezing force and attrition with the thinning of the gears resulting in the rejection of the gear wheels. Their lifetime can be prolonged if they are repaired with cast tungsten carbide powder. It is preferable to use tungsten carbide of fine grain size for such build-up welding.

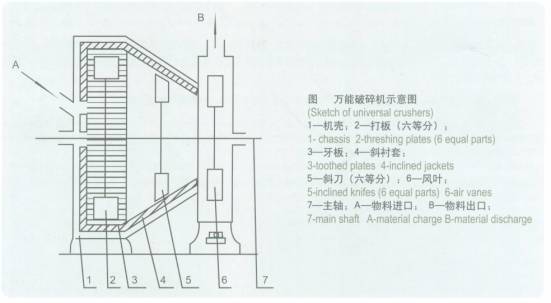

5. 万能破碎机易磨损件的堆焊:万能破碎机的牙板、打板、斜刀和斜衬套极易磨损,需经常停机更换。

衬套和牙板改为普通钢堆焊一层铸造碳化钨后,使用寿命较原来提高15倍,不仅提高了产品质量,总成本也较原来降低七倍多。

The build-up welding of wear parts of universal crushers: The toothed plates, threshing plates, inclined knives and jackets of crushers are parts that wear easily and have to be changed frequently with the machine shut down, If the inclined jackets and toothed plates are changed to conventional steel with a layer of cast tungsten carbide build-up welded on, their lifetime can be increased by 15 times. It not only improves the quality of the products, but also reduces the total cost by more than 7 times.

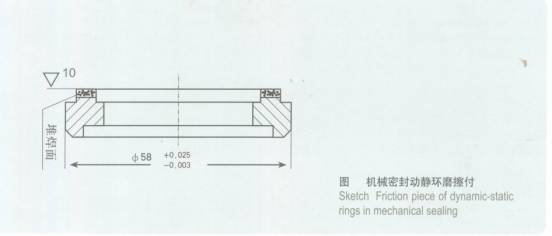

6. 机械密封动静环磨擦付(如图),不平度和光洁度要求都很高,用填料密封,每周要更换一次,后用GT35钢结合金,也只能用一个月,最后,采用铸造碳化钨堆焊,焊后用碳化硅砂轮研磨抛光,精度和光洁度都能达到要求,经使用三个月,仍未出现异常现象,尚在继续使用。

Friction piece of dynamic-static ring in mechanical sealing(shown in the sketch)is a part that requires a high flatness and surface finish. It is sealed with stuffing material and has to be changed once a week. It lasts only one month after it is changed to GT35 steel bonded carbide. And in the end cast tungsten carbide is used for build-up welding and then ground and polished with silicon carbide wheels. It reaches the desired flatness and surface finish and it is still working after 3 months of operations without any abnormal phenomenon.

7. 石油钻探行业用的金刚石钻头,用粒度为80—200目的铸造碳化钨粉作骨架,采用无压浸渍工艺,以铜合金作钎焊料,将铸造碳化钨与基体牢固结合,强度、耐磨性大大提高。被目前石油钻探行业广泛应用。

The strength and wear resistance of diamond drill bits for petroleum exploitation will be increased considerably when cast tungsten carbide is applied and adheres to the substrate firmly with cast tungsten carbide of 80-200mesh as the skelton and copper alloy as the soldering material in a process of non-pressure immersion. It has been widely used in the industry of petroleum exploitation.

铸造碳化钨的堆焊

- 氧—乙炔焰堆焊法

管装粒状铸造碳化钨主要是用氧—乙炔焰进行堆焊。在堆焊过程中,铸造碳化钨颗粒本身并不熔化,而是代理助于熔化后的钢管和基体金属将铸造碳化钨粘附于工件上。堆焊温度一般为1600—1700OC,在这样的温度下,铸造碳化钨合金不会发生组织转变。因此,仍保持它原有的高硬度和高耐磨性的特点。堆焊时必须注意下列几点:

Tubular cast tungsten carbide is build-up welded mainly by means of oxygen-acetylene flames. Cast tungsten carbide grains do not melt themselves and they adhere to the workpieces with the help of molten steel tubes and substrate metals. Normally the temperature for build-up welding is 1600—1700OC.There will be no change in the structure of cast tungsten carbide at such a temperatures and it still keeps its original high hardness and wear resistance. Attention should be paid to the following:

- 堆焊前,被堆焊表面应用钢刷仔细清理,不应有油污、锈迹和氧化皮等;

Before build-up welding is to be done, the surface of the part to be build-up welded must be cleaned with a steel brush &free of greasy dirt, tust and oxidized skin, etc.

- 堆焊前,堆焊件表面必须放平,以保证堆焊时铸造碳化钨颗粒均匀分布;

Before build-up welding is to be done, the parts to be welded must be in a flat position to ensure the even distribution of cast tuntgsten carbide grains during the build-up welding.

- 堆焊时,首先应用火焰将堆焊件表面的基体金属预热到朦胧状,由模糊状变为萤萤发光,形成一层极薄的熔融金属时,方可进行堆焊;

When the welding is being done, the substrate metals on the surface of the parts to be welded should be preheated to a state of haziness and then to a fluorescent light forming a very thin layer of molten metal, and only then build-up welding can be done.

- 用氧—乙炔焰堆焊时,应用还原焰,氧:乙炔<1.0:1.3,即作用微过量的乙炔,以保证堆焊层表面及堆焊金属不被氧化。同时,可以使燃尽的碳成分达到最小;

When build-up welding is done with oxygen-acetylene, reducing flames should be applied, oxygen: acetylene <1.0:1.3,and that is to say a little excess acetylene is used to ensure that the surface of the welded layer and the welded metal will not be oxidized. At the same time, it can ensure as little as possible thw burned carbon content.

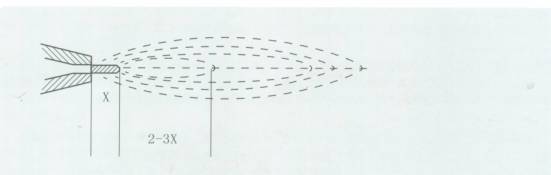

- 堆焊时采用的喷嘴,根据堆焊件的大小和堆焊前的加热程度来选择。如堆焊中等规格的牙轮钻头,采用4号喷嘴,乙炔消耗量为750升/小时。堆焊过程中,火焰调整好后,还原焰心长度的2—3倍为宜,如图所示:

The nozzles for build-up welding are to be selected based on the dimensions of the parts to be welde and the extent of heating before they are welded. Tricone bits of medium sizes are to be welded with number4nozzles with a consumption rate of acetylene at 750 l/hr. During the build-up welding, the length of the reducing flames is desirably 2-3times that of the flame core as shown in the Sketch.

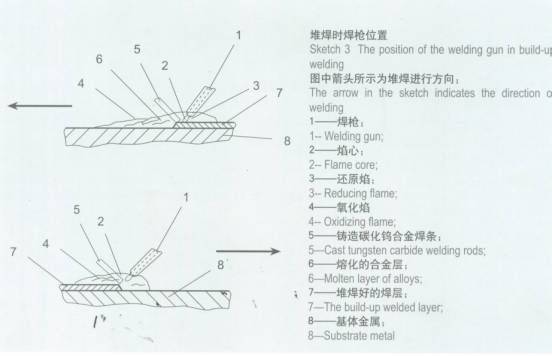

- 堆焊过程中,为避免铸造碳化钨颗粒被氧化,焰心与被堆焊工件表面之间的距离,应保持2~3MM.为了尽快地加热堆焊表面,又避免堆焊表面过热和融化,同时预热相邻里堆焊部位,焊枪中心线应与堆焊表面约成15度~25度倾向,如图所示:

During welding the distance between the flame core and the surface of the part to be welded should be kept at 2~3mm, the center line of the welding gun should have an inclination of 15o~25 o in relation to the surface to be welded as shown in the sketch..

7. 堆焊时,应特别注意调解氧气的工作压力和火焰的情况。使用的乙炔不宜太过量,否则,在堆焊过程中,会产生大量的碳,以

致影响到堆焊质量,同时,还会降低融化温度,氧气的工作压力,一般为3~3.5/CM2

During build-up welding, special attention should be paid to the adjustment of the working pressure of oxygen

and of the flame. IT is advisable to have not too much of acetylene flame, as otherwise the quality of build-up

welding will be affected, porosity and cortex will be increased and the melting temperature will be decreased

due to too much carbon generated. The working pressure oxygen is normally 3-3.5kg/cm2.

在整个堆焊过程中,应注意堆焊温度,如温度 (待续)

有加工疑问请联系广州钻石施经理 (020—83556773)

|