人造金刚石(CVD、PCD)、立方氮化硼(PCBN)材料制成的刀具在国内外广泛用于汽车摩托车制造、通用机械,以及航空、军工、电子、石油、化工、医疗、木材和石材加工等行业。

金刚石膜刀具和聚晶金刚石刀具硬度高,耐磨性好、磨擦性好、磨擦系数小、抗粘接性强,用于有色金属的高光洁度加工。也适用于陶瓷、合成纤维等非金属材料工件的精密加工。立方化硼刀具硬度高、红硬性好(>1300(C)、抗粘接性强,用于高硬度黑色金属及合金、铸铁等材料的精加工,工件硬度可在HRC60以上。

Cutting tools made of synthetic diamond (CVD, PCD),poly-(cubic boron nitride)(PCBN)have been widely used in areas such as motorcycle manufacturing, aerospace, military industry, electronic, chemical engineering, petroleum industry, medical treatment, woodworking, etc. These kind of cutting tools have high hardness, good wear-resistance, low friction coefficient, can be used for high surface finishes machining of non-ferrous. They can also be used to machine inorganic materials such as ceramics and synthetic fibres with high precision. PCBN cutting tools have high hardness, good high temperature hardness((1300(C),can be used for high precision machining of high hardness materials such as non-ferrous and alloy, cast iron((60HRC),etc.

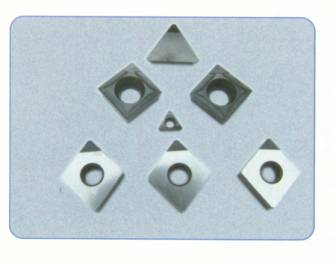

金刚石材料刀具

Superhard materials cutting tools

聚晶金刚石(PCD)刀具具有持久的耐用度、稳定的加工精度、良好的工件表面粗糙度等优良特性。用于有色金属和部分非金属材料的半精加工和精加工。

工件表面粗糙度:Ra1.6-0.16

刀具寿命:为硬质合金的几十倍—上百倍

PCD cutting tools have good properties such as longer tool life、stable machining precison、good surface roughness, etc, can be used for precision or semi-precision machining of non-ferrous and non-metallic materials.

Surface roughness of machined material: Ra0.16-1.6

Life of tools: several tens to hundred times of tungsten carbide.

聚晶立方氮化硼(PCBN)刀具具有硬度高、红硬性(>1300(C)好等特点。用于高硬度黑色金属和铸铁等材料的精加工。在金属加工中的许多场合可以车、镗、铣代替磨削工艺。由于在切削过程刀具对工件有挤压作用,这不但可提高工件表面光洁度,还可使工件表面产生加工硬化,提高工件的机械性能。

工件表面粗糙度:Ra0.3—1.6

刀具寿命:为硬质合金的几十倍以上

PCBN cutting tools have high hardness, good high temperature hardness (>1300(C),Used for high precision machining of high hardness materials such as ferrous metals and cast Iron. In some circumstances, turning, boring, milling are often used to instead cutting process. The surface roughness is improved by extrusion during cutting, and this process can also result in harder on surface and increase the mechanical properties of lorkpiece machined.

Surface roughness of machined material:Ra0.3-—1.6

Life of tools: tens of times of tungsten carbide

金刚石膜(CVD)刀具兼备聚晶金刚石和单晶金刚石刀具的优良特性,并在一定程度上克服了他们各自的不足。大量实践证明,金刚石膜(CVD)刀具使用寿命和加工光洁度均优于聚晶金刚石刀具,与单晶金刚石接近,而价格却远远低于价格昂贵的单晶金刚石刀具。是制造超硬材料刀具的理想材料。

CVD diamond cutting tools combine the good properties of PCD cutting tools and PCBN cutting tools, at the same time compensate some shortcomings of them in some degree. It has been proved that life and surface roughness of CVD diamond cutting tools are better than those of PCD cutting tools, and similar to single crystal diamond. But the price is much lower than that of single crystal diamond. CVD diamond is an ideal choice for cutting tools.

金刚石轴承工装

Diamond fixation for bearing processing

由人造金刚石和立方氮化硼材料制成的耐磨器件具有以下特性:

- 产品工作端面表面光洁度可达镜面(Ra<20nm),不会对工件表面产生划伤,并能保持工件原有的光亮度;

- 与硬质合金和陶瓷材料相比,金刚石和钢铁材料之间的磨擦系数最小,综合经济效益大大提高。

- 寿命长,耐用度高。使停机次数和生产辅助时间减少,废品率下降,综合经济效益大大提高。

本公司生产的金刚石轴承工装已达到或接近国外同类产品的水平,部分产品已出口日本、泰国、新加坡等国家。我们也可根据客户的需求进行设计、制造。

Advantages of wear-resistance components of synthetic diamond and PCBN:

- Surface roughness is equivalent to mirror (Ra<20nm).There is no damage to surface of works. Can retain the original brightness.

- Compared with cemented carbide and ceramics, diamond has the lowest friction coefficients with ion and steel, this reduces the friction force and improves the precision of machining of words.

- Long life and wear resistant .Longer Availability work time and lower wastrel rate, reduce the overall cost.

Our diamond bearing fixer can compete globally. Some series have been exported to Japan, Thailand and Singapore. We can also design and manufacture according to your requirements.

|